Page 37 - Tohnichi_CIP

P. 37

Tohnichi Reference Guide 2019

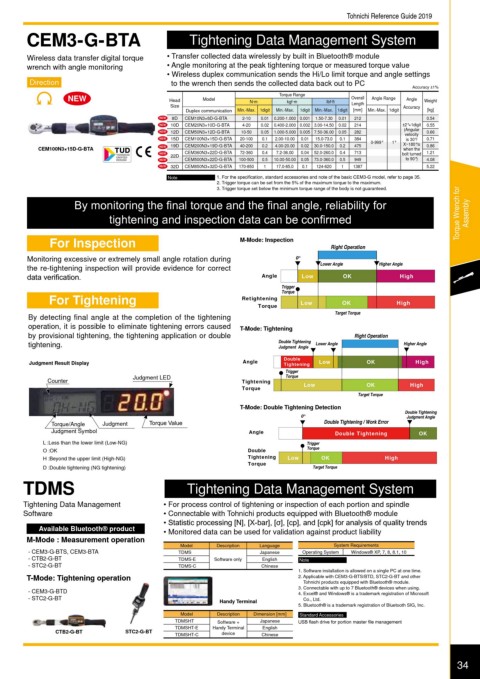

CEM3-G-BTA Tightening Data Management System

Wireless data transfer digital torque ? Transfer collected data wirelessly by built in Bluetooth® module

wrench with angle monitoring ? Angle monitoring at the peak tightening torque or measured torque value

? Wireless duplex communication sends the Hi/Lo limit torque and angle settings

Direction to the wrench then sends the collected data back out to PC

Accuracy ±1%

NEW Head Model N·m Torque Range lbf·ft Overall Angle Range Angle Weight

kgf·m

Size Length Accuracy

Duplex communication Min.-Max. 1digit Min.-Max. 1digit Min.-Max. 1digit [mm] Min.-Max. 1digit [kg]

NEW 8D CEM10N3×8D-G-BTA 2-10 0.01 0.200-1.000 0.001 1.50-7.30 0.01 212 0.54

NEW 10D CEM20N3×10D-G-BTA 4-20 0.02 0.400-2.000 0.002 3.00-14.50 0.02 214 ±2°+1digit 0.55

NEW 12D CEM50N3×12D-G-BTA 10-50 0.05 1.000-5.000 0.005 7.50-36.00 0.05 282 (Angular 0.66

velocity

NEW 15D CEM100N3×15D-G-BTA 20-100 0.1 2.00-10.00 0.01 15.0-73.0 0.1 384 0-999° 1° is 30°/ 0.71

CEM100N3×15D-G-BTA NEW 19D CEM200N3×19D-G-BTA 40-200 0.2 4.00-20.00 0.02 30.0-150.0 0.2 475 X~180°/s 0.86

when the

NEW CEM360N3×22D-G-BTA 72-360 0.4 7.2-36.00 0.04 52.0-260.0 0.4 713 bolt turned 1.21

22D

NEW CEM500N3×22D-G-BTA 100-500 0.5 10.00-50.00 0.05 73.0-360.0 0.5 949 to 90°) 4.08

NEW 32D CEM850N3×32D-G-BTA 170-850 1 17.0-85.0 0.1 124-620 1 1387 5.22

Note 1. For the speci?cation, standard accessories and note of the basic CEM3-G model, refer to page 35.

2. Trigger torque can be set from the 5% of the maximum torque to the maximum.

3. Trigger torque set below the minimum torque range of the body is not guaranteed.

By monitoring the ?nal torque and the ?nal angle, reliability for

tightening and inspection data can be con?rmed Torque Wrench for Assembly

For Inspection M-Mode: Inspection Right Operation

Monitoring excessive or extremely small angle rotation during 0°

the re-tightening inspection will provide evidence for correct Lower Angle Higher Angle

data veri?cation. Angle Low OK High

Trigger

Torque

For Tightening Retightening Low OK High

Torque

By detecting final angle at the completion of the tightening Target Torque

operation, it is possible to eliminate tightening errors caused T-Mode: Tightening

by provisional tightening, the tightening application or double Right Operation

tightening. Double Tightening Lower Angle OK Higher Angle

Judgment Angle

Judgment Result Display Angle Double Low OK High

Tightening

Trigger

Judgment LED Torque

Counter Tightening

Torque Low OK High

Target Torque

T-Mode: Double Tightening Detection

0° Double Tightening

Judgment Angle

Torque/Angle Judgment Torque Value Double Tightening / Work Error

Judgment Symbol Angle Double Tightening OK

L :Less than the lower limit (Low-NG) Trigger

O :OK Double Torque

H :Beyond the upper limit (High-NG) Tightening Low OK High

Torque

D :Double tightening (NG tightening) Target Torque

TDMS Tightening Data Management System

Tightening Data Management ? For process control of tightening or inspection of each portion and spindle

Software ? Connectable with Tohnichi products equipped with Bluetooth® module

? Statistic processing [N], [X-bar], [?], [cp], and [cpk] for analysis of quality trends

Available Bluetooth® product ? Monitored data can be used for validation against product liability

M-Mode : Measurement operation

Model Description Language System Requirements

- CEM3-G-BTS, CEM3-BTA TDMS Japanese Operating System Windows® XP, 7, 8, 8.1, 10

- CTB2-G-BT TDMS-E Software only English Note

- STC2-G-BT TDMS-C Chinese

1. Software installation is allowed on a single PC at one time.

T-Mode: Tightening operation 2. Applicable with CEM3-G-BTS/BTD, STC2-G-BT and other

Tohnichi products equipped with Bluetooth® module.

3. Connectable with up to 7 Bluetooth® devices when using.

- CEM3-G-BTD 4. Excel® and Windows® is a trademark registration of Microsoft

- STC2-G-BT Handy Terminal Co., Ltd.

5. Bluetooth® is a trademark registration of Bluetooth SIG, Inc.

Model Description Dimension [mm] Standard Accessories

TDMSHT Software + Japanese USB flash drive for portion master ?le management

TDMSHT-E Handy Terminal English

CTB2-G-BT STC2-G-BT

TDMSHT-C device Chinese

34