Page 39 - Tohnichi_CIP

P. 39

Tohnichi Reference Guide 2019

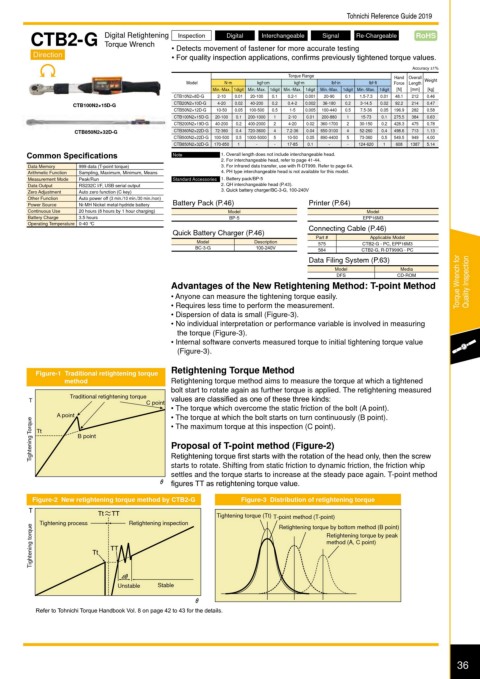

CTB2-G Digital Retightening Inspection Digital Interchangeable Signal Re-Chargeable RoHS

Torque Wrench

Direction ? Detects movement of fastener for more accurate testing

? For quality inspection applications, con?rms previously tightened torque values.

Accuracy ±1%

Torque Range Hand Overall

Model N·m kgf·cm kgf·m lbf·in lbf·ft Force Length Weight

Min.-Max. 1digit Min.-Max. 1digit Min.-Max. 1digit Min.-Max. 1digit Min.-Max. 1digit [N] [mm] [kg]

CTB10N2×8D-G 2-10 0.01 20-100 0.1 0.2-1 0.001 20-90 0.1 1.5-7.3 0.01 48.1 212 0.46

CTB100N2×15D-G CTB20N2×10D-G 4-20 0.02 40-200 0.2 0.4-2 0.002 36-180 0.2 3-14.5 0.02 92.2 214 0.47

CTB50N2×12D-G 10-50 0.05 100-500 0.5 1-5 0.005 100-440 0.5 7.5-36 0.05 196.9 282 0.58

CTB100N2×15D-G 20-100 0.1 200-1000 1 2-10 0.01 200-880 1 15-73 0.1 275.5 384 0.63

CTB200N2×19D-G 40-200 0.2 400-2000 2 4-20 0.02 360-1700 2 30-150 0.2 428.3 475 0.78

CTB850N2×32D-G CTB360N2×22D-G 72-360 0.4 720-3600 4 7.2-36 0.04 650-3100 4 52-260 0.4 498.6 713 1.13

CTB500N2×22D-G 100-500 0.5 1000-5000 5 10-50 0.05 890-4400 5 73-360 0.5 549.5 949 4.00

CTB850N2×32D-G 170-850 1 - - 17-85 0.1 - - 124-620 1 608 1387 5.14

Common Specifications Note 1. Overall length does not include interchangeable head.

2. For interchangeable head, refer to page 41-44.

Data Memory 999 data (T-point torque) 3. For infrared data transfer, use with R-DT999. Refer to page 64.

Arithmetic Function Sampling, Maximum, Minimum, Means 4. PH type interchangeable head is not available for this model.

Measurement Mode Peak/Run Standard Accessories 1. Battery pack/BP-5

Data Output RS232C I/F, USB serial output 2. QH interchangeable head (P.43).

Zero Adjustment Auto zero function (C key) 3. Quick battery charger/BC-3-G, 100-240V

Other Function Auto power off (3 min./10 min./30 min./non) Battery Pack (P.46) Printer (P.64)

Power Source Ni-MH Nickel metal-hydride battery

Continuous Use 20 hours (8 hours by 1 hour charging) Model Model

Battery Charge 3.5 hours BP-5 EPP16M3

Operating Temperature 0-40 °C Connecting Cable (P.46)

Quick Battery Charger (P.46)

Part # Applicable Model

Model Description 575 CTB2-G - PC, EPP16M3

BC-3-G 100-240V 584 CTB2-G, R-DT999G - PC

Data Filing System (P.63)

Model Media

DFS CD-ROM

Advantages of the New Retightening Method: T-point Method Torque Wrench for Quality Inspection

? Anyone can measure the tightening torque easily.

? Requires less time to perform the measurement.

? Dispersion of data is small (Figure-3).

? No individual interpretation or performance variable is involved in measuring

the torque (Figure-3).

? Internal software converts measured torque to initial tightening torque value

(Figure-3).

Retightening Torque Method

Figure-1 Traditional retightening torque

method Retightening torque method aims to measure the torque at which a tightened

bolt start to rotate again as further torque is applied. The retightening measured

Traditional retightening torque values are classi?ed as one of these three kinds:

T C point

? The torque which overcome the static friction of the bolt (A point).

A point ? The torque at which the bolt starts on turn continuously (B point).

Tightening Torque Tt B point Proposal of T-point method (Figure-2)

? The maximum torque at this inspection (C point).

Retightening torque ?rst starts with the rotation of the head only, then the screw

starts to rotate. Shifting from static friction to dynamic friction, the friction whip

settles and the torque starts to increase at the steady pace again. T-point method

?gures TT as retightening torque value.

Figure-2 New retightening torque method by CTB2-G Figure-3 Distribution of retightening torque

Tightening torque (Tt) T-point method (T-point)

Tightening process Retightening inspection Retightening torque by bottom method (B point)

Tightening torque Retightening torque by peak

method (A, C point)

Unstable Stable

Refer to Tohnichi Torque Handbook Vol. 8 on page 42 to 43 for the details.

36