Page 68 - Tohnichi_CIP

P. 68

Tohnichi Reference Guide 2019

Torque Settings for Torque Screwdrivers

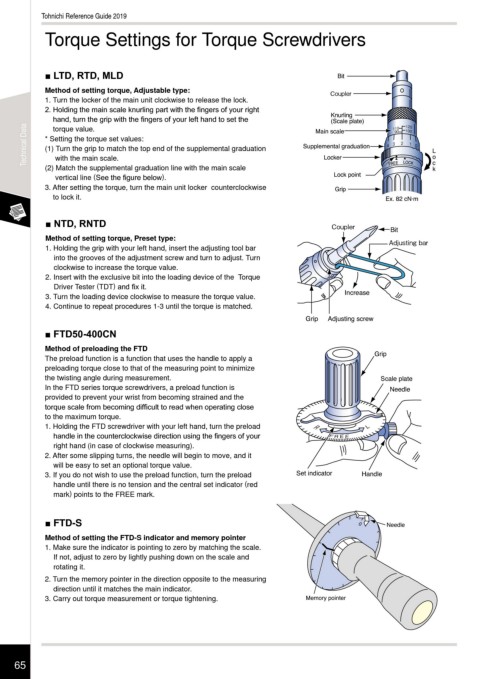

? LTD, RTD, MLD %LW

Method of setting torque, Adjustable type: $PVQMFS

1. Turn the locker of the main unit clockwise to release the lock.

2. Holding the main scale knurling part with the ?ngers of your right

.QXUOLQJ

hand, turn the grip with the ?ngers of your left hand to set the 0DLQ VFDOH

6FDOH SODWH

Technical Data * Setting the torque set values: 6XSSOHPHQWDO JUDGXDWLRQ /

torque value.

(1) Turn the grip to match the top end of the supplemental graduation

with the main scale.

(2) Match the supplemental graduation line with the main scale /RFNHU R F N

vertical line (See the ?gure below). /RFN SRLQW

3. After setting the torque, turn the main unit locker counterclockwise *ULS

to lock it. ([ F1ĂP

? NTD, RNTD $PVQMFS

%LW

Method of setting torque, Preset type: "EKVTUJOH CBS

1. Holding the grip with your left hand, insert the adjusting tool bar

into the grooves of the adjustment screw and turn to adjust. Turn

clockwise to increase the torque value.

2. Insert with the exclusive bit into the loading device of the Torque

Driver Tester (TDT) and ?x it.

3. Turn the loading device clockwise to measure the torque value. ,QFUHDVH

4. Continue to repeat procedures 1-3 until the torque is matched.

*ULS $GMXVWLQJ VFUHZ

? FTD50-400CN

Method of preloading the FTD

The preload function is a function that uses the handle to apply a *ULS

preloading torque close to that of the measuring point to minimize

the twisting angle during measurement. 6FDOH SODWH

In the FTD series torque screwdrivers, a preload function is 1HHGOH

provided to prevent your wrist from becoming strained and the

torque scale from becoming dif?cult to read when operating close

to the maximum torque.

1. Holding the FTD screwdriver with your left hand, turn the preload 3 -

handle in the counterclockwise direction using the ?ngers of your ' 3 & &

right hand (in case of clockwise measuring).

2. After some slipping turns, the needle will begin to move, and it

will be easy to set an optional torque value.

3. If you do not wish to use the preload function, turn the preload 6HW LQGLFDWRU +DQGOH

handle until there is no tension and the central set indicator (red

mark) points to the FREE mark.

? FTD-S 1HHGOH

Method of setting the FTD-S indicator and memory pointer

1. Make sure the indicator is pointing to zero by matching the scale.

If not, adjust to zero by lightly pushing down on the scale and

rotating it.

2. Turn the memory pointer in the direction opposite to the measuring

direction until it matches the main indicator.

3. Carry out torque measurement or torque tightening. 0HPRU\ SRLQWHU

65