Page 53 - Tohnichi_CIP

P. 53

Tohnichi Reference Guide 2019

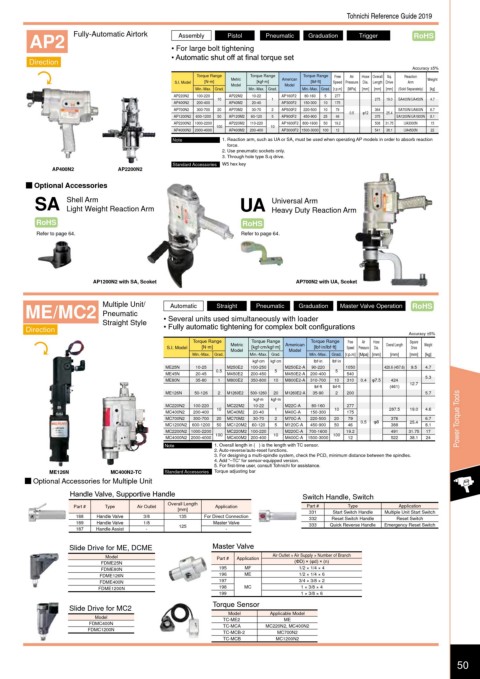

AP2 Fully-Automatic Airtork ? For large bolt tightening Pneumatic Graduation Trigger RoHS

Pistol

Assembly

? Automatic shut off at ?nal torque set

Direction

Accuracy ±5%

Torque Range Torque Range Torque Range Free Air Hose Overall Sq. Reaction

S.I. Model [N·m] Metric [kgf·m] American [Ibf·ft] Speed Pressure Dia. Length Drive Arm Weight

Model Model

Min.-Max. Grad. Min.-Max. Grad. Min.-Max. Grad. [r.p.m] [MPa] [mm] [mm] [mm] (Sold Separately) [kg]

AP220N2 100-220 AP22M2 10-22 AP160F2 80-160 5 277

10 1 275 19.0 SA400N/UA450N 4.7

AP400N2 200-400 AP40M2 20-40 AP300F2 150-300 10 175

AP700N2 300-700 20 AP70M2 30-70 2 AP500F2 220-500 10 79 364 SA700N/UA900N 6.7

0.5 ?12 25.4

AP1200N2 600-1200 50 AP120M2 60-120 5 AP900F2 450-900 25 46 375 SA1200N/UA1800N 8.1

AP2200N2 1000-2200 AP220M2 110-220 AP1600F2 800-1600 50 19.2 508 31.75 UA3000N 15

100 10

AP4000N2 2000-4000 AP400M2 200-400 AP3000F2 1500-3000 100 12 541 38.1 UA4500N 22

Note 1. Reaction arm, such as UA or SA, must be used when operating AP models in order to absorb reaction

force.

2. Use pneumatic sockets only.

3. Through hole type S.q drive.

Standard Accessories W5 hex key

AP400N2 AP2200N2

Optional Accessories

SA Shell Arm UA Universal Arm

Light Weight Reaction Arm

Heavy Duty Reaction Arm

RoHS RoHS

Refer to page 64. Refer to page 64.

AP1200N2 with SA, Scoket AP700N2 with UA, Scoket

ME/MC2 Multiple Unit/ Automatic Straight Pneumatic Graduation Master Valve Operation RoHS

Pneumatic

Straight Style ? Several units used simultaneously with loader

Direction ? Fully automatic tightening for complex bolt con?gurations

Accuracy ±5%

Torque Range Torque Range Torque Range Free Air Hose Square

S.I. Model [N·m] Metric [kgf·cm/kgf·m] American [lbf·in/lbf·ft] Speed Pressure Dia. Overall Length Drive Weight

Model

Model

Min.-Max. Grad. Min.-Max. Grad. Min.-Max. Grad. [r.p.m] [Mpa] [mm] [mm] [mm] [kg]

kgf·cm kgf·cm lbf·in lbf·in

ME25N 10-25 M250E2 100-250 M250E2-A 90-220 1050 420.6 (457.6) 9.5 4.7

ME45N 20-45 0.5 M450E2 200-450 5 M450E2-A 200-400 5 540

ME80N 35-80 1 M800E2 350-800 10 M800E2-A 310-700 10 310 0.4 ?7.5 424 12.7 5.3

lbf·ft lbf·ft (461)

ME126N 50-126 2 M1260E2 500-1260 20 M1260E2-A 35-90 2 200 5.7

kgf·m kgf·m

MC220N2 100-220 10 MC22M2 10-22 1 M22C-A 80-160 10 277 287.5 19.0 4.6

MC400N2 200-400 MC40M2 20-40 M40C-A 150-300 175

MC700N2 300-700 20 MC70M2 30-70 2 M70C-A 220-500 20 79 0.5 ?8 376 25.4 6.7 Power Torque Tools

MC1200N2 600-1200 50 MC120M2 60-120 5 M120C-A 450-900 50 46 388 8.1

MC2200N2 1000-2200 MC220M2 100-220 M220C-A 700-1600 19.2 491 31.75 17

MC4000N2 2000-4000 100 MC400M2 200-400 10 M400C-A 1500-3000 100 12 522 38.1 24

Note 1. Overall length in ( ) is the length with TC sensor.

2. Auto-reverse/auto-reset functions.

3. For designing a multi-spindle system, check the PCD, minimum distance between the spindles.

4. Add ??TC? for sensor-equipped version.

5. For ?rst-time user, consult Tohnichi for assistance.

ME126N MC400N2-TC Standard Accessories Torque adjusting bar

Optional Accessories for Multiple Unit

Handle Valve, Supportive Handle Switch Handle, Switch

Overall Length

Part # Type Air Outlet Application Part # Type Application

[mm] 331 Start Switch Handle Multiple Unit Start Switch

188 Handle Valve 3/8 135 For Direct Connection 332 Reset Switch Handle Reset Switch

189 Handle Valve 1/8 Master Valve 333 Quick Reverse Handle Emergency Reset Switch

187 Handle Assist - 125 -

Slide Drive for ME, DCME Master Valve

Model Part # Application Air Outlet × Air Supply × Number of Branch

FDME25N (?D) × (?d) × (n)

FDME80N 195 MF 1/2 × 1/4 × 4

FDME126N 196 ME 1/2 × 1/4 × 6

FDME400N 197 3/4 × 3/8 × 2

FDME1200N 198 MC 1 × 3/8 × 4

199 1 × 3/8 × 6

Torque Sensor

Slide Drive for MC2

Model

Model TC-ME2 Applicable Model

ME

FDMC400N

FDMC1200N TC-MCA MC220N2, MC400N2

TC-MCB-2 MC700N2

TC-MCB MC1200N2

50