Page 26 - Tohnichi_CIP

P. 26

Tohnichi Reference Guide 2019

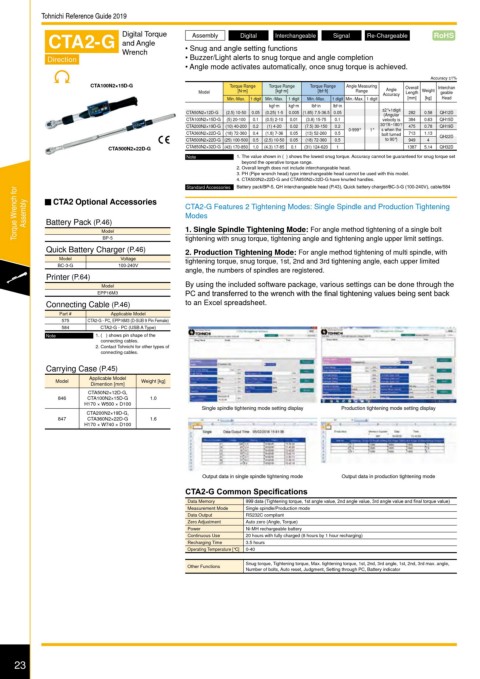

CTA2-G Digital Torque Assembly Digital Interchangeable Signal Re-Chargeable RoHS

and Angle

Wrench ? Snug and angle setting functions

Direction ? Buzzer/Light alerts to snug torque and angle completion

? Angle mode activates automatically, once snug torque is achieved.

Accuracy ±1%

CTA100N2×15D-G Torque Range Torque Range Torque Range Angle Measuring Overall Interchan

Angle

Model [N·m] [kgf·m] [lbf·ft] Range Accuracy Length Weight geable

Min.-Max. 1 digit Min.-Max. 1 digit Min.-Max. 1 digit Min.-Max. 1 digit [mm] [kg] Head

kgf·m kgf·m lbf·in lbf·in

CTA50N2×12D-G (2.5) 10-50 0.05 (0.25) 1-5 0.005 (1.85) 7.5-36.5 0.05 ±2°+1digit 282 0.58 QH12D

(Angular

CTA100N2×15D-G (5) 20-100 0.1 (0.5) 2-10 0.01 (3.8) 15-75 0.1 velocity is 384 0.63 QH15D

CTA200N2×19D-G (10) 40-200 0.2 (1) 4-20 0.02 (7.5) 30-150 0.2 0-999° 1° 30°/X~180°/ 475 0.78 QH19D

s when the

CTA360N2×22D-G (18) 72-360 0.4 (1.8) 7-36 0.05 (13) 52-260 0.5 bolt turned 713 1.13 QH22D

CTA500N2×22D-G (25) 100-500 0.5 (2.5) 10-50 0.05 (18) 72-360 0.5 to 90°) 949 4

CTA500N2×22D-G CTA850N2×32D-G (43) 170-850 1.0 (4.3) 17-85 0.1 (31) 124-620 1 1387 5.14 QH32D

Note 1. The value shown in ( ) shows the lowest snug torque. Accuracy cannot be guaranteed for snug torque set

beyond the operative torque range.

2. Overall length does not include interchangeable head.

3. PH (Pipe wrench head) type interchangeable head cannot be used with this model.

4. CTA500N2×22D-G and CTA850N2×32D-G have knurled handles.

Standard Accessories

Battery pack/BP-5, QH interchangeable head (P.43), Quick battery charger/BC-3-G (100-240V), cable/584

Torque Wrench for Assembly Battery Pack (P.46) CTA2-G Features 2 Tightening Modes: Single Spindle and Production Tightening

CTA2 Optional Accessories

Modes

1. Single Spindle Tightening Mode: For angle method tightening of a single bolt

Model

BP-5

Quick Battery Charger (P.46) tightening with snug torque, tightening angle and tightening angle upper limit settings.

2. Production Tightening Mode: For angle method tightening of multi spindle, with

Model Voltage tightening torque, snug torque, 1st, 2nd and 3rd tightening angle, each upper limited

BC-3-G 100-240V

angle, the numbers of spindles are registered.

Printer (P.64)

Model By using the included software package, various settings can be done through the

EPP16M3 PC and transferred to the wrench with the ?nal tightening values being sent back

Connecting Cable (P.46) to an Excel spreadsheet.

Part # Applicable Model

575 CTA2-G - PC, EPP16M3 (D-SUB 9 Pin Female)

584 CTA2-G - PC (USB A Type)

Note 1. ( ) shows pin shape of the

connecting cables.

2. Contact Tohnichi for other types of

connecting cables.

Carrying Case (P.45)

Applicable Model

Model Dimention [mm] Weight [kg]

CTA50N2×12D-G,

846 CTA100N2×15D-G 1.0

H170 × W500 × D100

Single spindle tightening mode setting display Production tightening mode setting display

CTA200N2×19D-G,

847 CTA360N2×22D-G 1.6

H170 × W740 × D100

Output data in single spindle tightening mode Output data in production tightening mode

CTA2-G Common Specifications

Data Memory 999 data (Tightening torque, 1st angle value, 2nd angle value, 3rd angle value and ?nal torque value)

Measurement Mode Single spindle/Production mode

Data Output RS232C compliant

Zero Adjustment Auto zero (Angle, Torque)

Power Ni-MH rechargeable battery

Continuous Use 20 hours with fully charged (8 hours by 1 hour recharging)

Recharging Time 3.5 hours

Operating Temperature [°C] 0-40

Snug torque, Tightening torque, Max. tightening torque, 1st, 2nd, 3rd angle, 1st, 2nd, 3rd max. angle,

Other Functions Number of bolts, Auto reset, Judgment, Setting through PC, Battery indicator

23