Page 23 - Tohnichi_CIP

P. 23

Tohnichi Reference Guide 2019

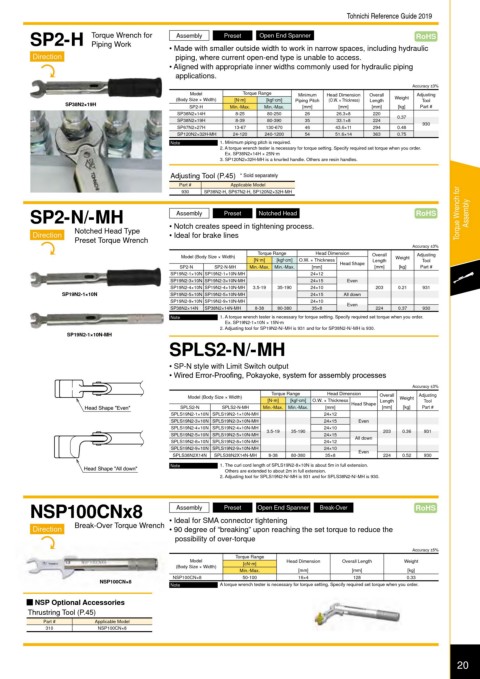

SP2-H Torque Wrench for Assembly Preset Open End Spanner RoHS

Piping Work

Direction ? Made with smaller outside width to work in narrow spaces, including hydraulic

piping, where current open-end type is unable to access.

? Aligned with appropriate inner widths commonly used for hydraulic piping

applications.

Accuracy ±3%

Model Torque Range Minimum Head Dimension Overall Adjusting

(Body Size × Width) [N·m] [kgf·cm] Piping Pitch (O.W. × Thickness) Length Weight Tool

SP38N2×19H SP2-H Min.-Max. Min.-Max. [mm] [mm] [mm] [kg] Part #

SP38N2×14H 8-25 80-250 26 26.3×8 220 0.37

SP38N2×19H 8-39 80-390 35 33.1×8 224 930

SP67N2×27H 13-67 130-670 46 43.6×11 294 0.48

SP120N2×32H-MH 24-120 240-1200 54 51.6×14 363 0.75

Note 1. Minimum piping pitch is required.

2. A torque wrench tester is necessary for torque setting. Specify required set torque when you order.

Ex. SP38N2×14H × 25N·m

3. SP120N2×32H-MH is a knurled handle. Others are resin handles.

Adjusting Tool (P.45) * Sold separately

Part # Applicable Model

930 SP38N2-H, SP67N2-H, SP120N2×32H-MH

SP2-N/-MH Assembly Preset Notched Head RoHS Torque Wrench for Assembly

? Ideal for brake lines

Direction Notched Head Type ? Notch creates speed in tightening process.

Preset Torque Wrench

Accuracy ±3%

Torque Range Head Dimension

Model (Body Size × Width) Overall Weight Adjusting

[N·m] [kgf·cm] O.W. × Thickness Length Tool

SP2-N SP2-N-MH Min.-Max. Min.-Max. [mm] Head Shape [mm] [kg] Part #

SP19N2-1×10N SP19N2-1×10N-MH 24×12

SP19N2-3×10N SP19N2-3×10N-MH 24×15 Even

SP19N2-4×10N SP19N2-4×10N-MH 3.5-19 35-190 24×10 203 0.21 931

SP19N2-1×10N SP19N2-5×10N SP19N2-5×10N-MH 24×15 All down

SP19N2-9×10N SP19N2-9×10N-MH 24×10

SP38N2×14N SP38N2×14N-MH 8-38 80-380 35×8 Even 224 0.37 930

Note 1. A torque wrench tester is necessary for torque setting. Specify required set torque when you order.

Ex. SP19N2-1×10N × 15N·m

2. Adjusting tool for SP19N2-N/-MH is 931 and for for SP38N2-N/-MH is 930.

SP19N2-1×10N-MH

SPLS2-N/-MH

? SP-N style with Limit Switch output

? Wired Error-Proo?ng, Pokayoke, system for assembly processes

Accuracy ±3%

Torque Range Head Dimension

Model (Body Size × Width) Overall Weight Adjusting

[N·m] [kgf·cm] O.W. × Thickness Head Shape Length Tool

+HDG 6KDSH (YHQ SPLS2-N SPLS2-N-MH Min.-Max. Min.-Max. [mm] [mm] [kg] Part #

SPLS19N2-1×10N SPLS19N2-1×10N-MH 24×12

SPLS19N2-3×10N SPLS19N2-3×10N-MH 24×15 Even

SPLS19N2-4×10N SPLS19N2-4×10N-MH 3.5-19 35-190 24×10 203 0.36 931

SPLS19N2-5×10N SPLS19N2-5×10N-MH 24×15 All down

SPLS19N2-8×10N SPLS19N2-8×10N-MH 24×12

SPLS19N2-9×10N SPLS19N2-9×10N-MH 24×10 Even

SPLS38N2X14N SPLS38N2X14N-MH 8-38 80-380 35×8 224 0.52 930

+HDG 6KDSH $OO GRZQ Note 1. The curl cord length of SPLS19N2-8×10N is about 5m in full extension.

Others are extended to about 2m in full extension.

2. Adjusting tool for SPLS19N2-N/-MH is 931 and for SPLS38N2-N/-MH is 930.

NSP100CNx8 Assembly Preset Open End Spanner Break-Over RoHS

Direction Break-Over Torque Wrench ? Ideal for SMA connector tightening

? 90 degree of ?breaking? upon reaching the set torque to reduce the

possibility of over-torque

Accuracy ±5%

Torque Range

Model [cN·m] Head Dimension Overall Length Weight

(Body Size × Width)

Min.-Max. [mm] [mm] [kg]

NSP100CN×8 50-100 16×4 128 0.33

NSP100CN×8

Note A torque wrench tester is necessary for torque setting. Specify required set torque when you order.

NSP Optional Accessories

Thrustring Tool (P.45)

Part # Applicable Model

310 NSP100CN×8

20