Page 20 - Tohnichi_CIP

P. 20

Tohnichi Reference Guide 2019

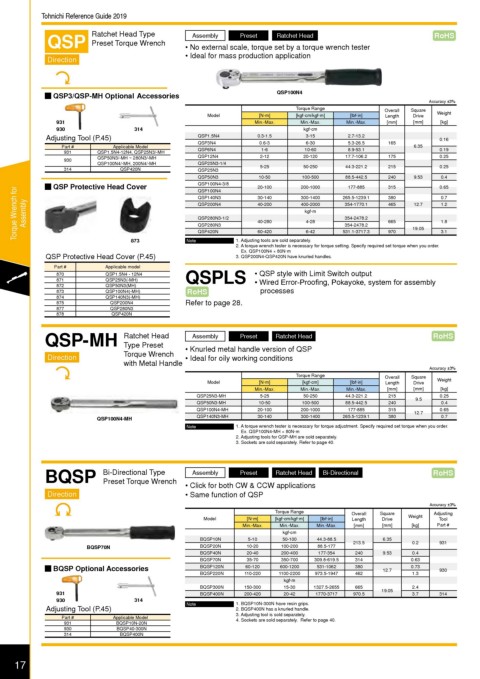

QSP Ratchet Head Type ? No external scale, torque set by a torque wrench tester RoHS

Ratchet Head

Preset

Assembly

Preset Torque Wrench

Direction ? Ideal for mass production application

QSP3/QSP-MH Optional Accessories QSP100N4

Accuracy ±3%

Torque Range Overall Square

Model [N·m] [kgf·cm/kgf·m] [lbf·in] Length Drive Weight

931 Min.-Max. Min.-Max. Min.-Max. [mm] [mm] [kg]

930 314 kgf·cm

Adjusting Tool (P.45) QSP1.5N4 0.3-1.5 3-15 2.7-13.2 0.16

Part # Applicable Model QSP3N4 0.6-3 6-30 5.3-26.5 165 6.35

931 QSP1.5N4-12N4, QSP25N3/-MH QSP6N4 1-6 10-60 8.9-53.1 0.19

930 QSP50N3/-MH ~ 280N3/-MH QSP12N4 2-12 20-120 17.7-106.2 175 0.25

QSP100N4/-MH, 200N4/-MH QSP25N3-1/4

314 QSP420N QSP25N3 5-25 50-250 44.3-221.2 215 0.25

100-500

QSP50N3 20-100 200-1000 88.5-442.5 240 9.53 0.65

0.4

10-50

QSP100N4-3/8

QSP Protective Head Cover

315

177-885

Torque Wrench for Assembly QSP140N3 30-140 300-1400 265.5-1239.1 380 19.05 0.7

QSP100N4

12.7

465

QSP200N4

1.2

40-200

400-2000

354-1770.1

kgf·m

354-2478.2

QSP280N3-1/2

1.8

665

40-280

4-28

354-2478.2

QSP280N3

QSP420N

970

531.1-3717.3

60-420

6-42

873

1. Adjusting tools are sold separately.

Note

2. A torque wrench tester is necessary for torque setting. Specify required set torque when you order. 3.1

Ex. QSP100N4 × 80N·m

QSP Protective Head Cover (P.45) 3. QSP200N4-QSP420N have knurled handles.

Part # Applicable model

870 QSP1.5N4 - 12N4 QSPLS ? QSP style with Limit Switch output

871 QSP25N3(-MH) ? Wired Error-Proo?ng, Pokayoke, system for assembly

872 QSP50N3(MH)

873 QSP100N4(-MH) RoHS processes

874 QSP140N3(-MH)

875 QSP200N4 Refer to page 28.

877 QSP280N3

878 QSP420N

QSP-MH Ratchet Head Assembly Preset Ratchet Head RoHS

Type Preset

Direction Torque Wrench ? Knurled metal handle version of QSP

? Ideal for oily working conditions

with Metal Handle

Accuracy ±3%

Torque Range Overall Square

Model [N·m] [kgf·cm] [lbf·in] Length Drive Weight

Min.-Max. Min.-Max. Min.-Max. [mm] [mm] [kg]

QSP25N3-MH 5-25 50-250 44.3-221.2 215 9.5 0.25

QSP50N3-MH 10-50 100-500 88.5-442.5 240 0.4

QSP100N4-MH 20-100 200-1000 177-885 315 12.7 0.65

QSP100N4-MH QSP140N3-MH 30-140 300-1400 265.5-1239.1 380 0.7

Note 1. A torque wrench tester is necessary for torque adjustment. Specify required set torque when you order.

Ex. QSP100N4-MH × 80N·m

2. Adjusting tools for QSP-MH are sold separately.

3. Sockets are sold separately. Refer to page 40.

Bi-Directional Type Assembly Preset Ratchet Head Bi-Directional RoHS

BQSP Preset Torque Wrench

? Click for both CW & CCW applications

Direction ? Same function of QSP

Accuracy ±3%

Torque Range Overall Square Adjusting

Model [N·m] [kgf·cm/kgf·m] [lbf·in] Length Drive Weight Tool

Min.-Max. Min.-Max. Min.-Max. [mm] [mm] [kg] Part #

kgf·cm

BQSP10N 5-10 50-100 44.3-88.5 213.5 6.35 0.2 931

BQSP70N BQSP20N 10-20 100-200 88.5-177

BQSP40N 20-40 200-400 177-354 240 9.53 0.4

BQSP70N 35-70 350-700 309.8-619.5 314 0.63

BQSP Optional Accessories BQSP120N 60-120 600-1200 531-1062 380 12.7 0.73 930

BQSP220N 110-220 1100-2200 973.5-1947 462 1.3

kgf·m

BQSP300N 150-300 15-30 1327.5-2655 665 2.4

931 BQSP400N 200-420 20-42 1770-3717 970.5 19.05 3.7 314

930 314 Note 1. BQSP10N-300N have resin grips.

Adjusting Tool (P.45) 2. BQSP400N has a knurled handle.

3. Adjusting tool is sold separately.

Part # Applicable Model 4. Sockets are sold separately. Refer to page 40.

931 BQSP10N-20N

930 BQSP40-300N

314 BQSP400N

17